How Insulation can be Regenerative

By Kaja Kühl

This article is part of the Climate Action Lab at Wally Farms, a project diary to build a carbon negative dwelling –exploring architecture and design solutions that address the climate crisis. This article has been edited for length. read original HERE.

Since the two homes at Wally Farms have been completed, I have been spending some time thinking about how to illustrate the relevance of having used hemp lime (which is now completely invisible like most insulation products are) and how to scale up the conversation from two tiny homes to greater impact. Insulation — the underappreciated enabler of energy-efficiency is one issue for discussing greater impact.

The greater Impact of bio-based Insulation

At a recent conference, the brilliant Mae-ling Lokko, in a talk about biogenic materials called insulation “the low-hanging fruit.” While many material researchers are working to develop more complex applications for bio-based materials, I want to spend the next few minutes to lay out why this underappreciated and often overlooked building element, is not only a low-hanging fruit. Paying closer attention to the material choices we make for insulation has an outsized impact on emissions reduction and planet health.

The built environment sector is by far the largest emitter of greenhouse gasses, responsible for at least 37% of global emissions. Until recently, most of the attention in the sector has been on reducing the “operational carbon” of a building — the emissions created from heating, cooling and lighting.

In our project, insulation — the very thing we use to reduce operational carbon — was the single biggest driver for also lowering the embodied carbon of the buildings to approximately 18.5 kg CO2e/m2, 10% of the average home in North America and Europe.

While discussions about embodied carbon often point to mass timber as an alternative to concrete, insulation should get a little more attention for its (almost) effortless ability to reduce both, operational and embodied carbon.

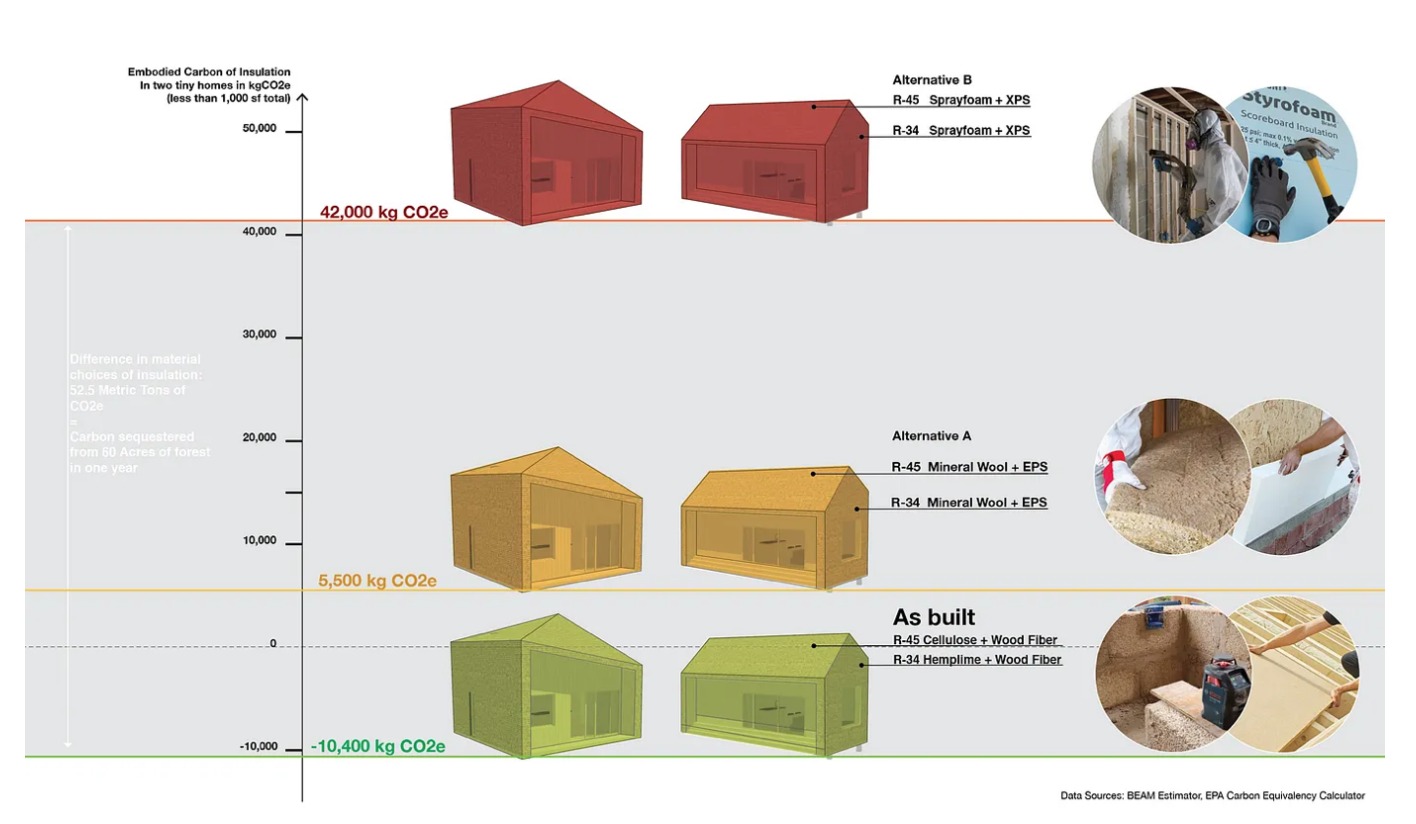

Three Scenarios of Embodied Carbon for Insulation for Roof and Walls in the hemp homes at Wally Farms

Using hemp lime + wood fiber for walls, cellulose and wood fiber boards in the roofs as insulation stores an estimated 10.4 metric tons of CO2e in the two tiny homes of 300 and 400 sq ft. Compare this with two scenarios where we would exchange the bio-based material with more conventional insulation (in similar proportions of cavity insulation and continuous rigid insulation).

The difference between our project and using spray-foam/XPS is 52.5 metric tonnes of CO2e — an amount equivalent to what 62 acres of forest sequester in one year or 135,000 miles driven in a passenger vehicle.

Keep in mind that this number is for insulating two tiny homes –less than 1,000 sf total. The two homes are powered by renewable energy. Their operational emissions are already zero. The only emissions from these two homes are embodied carbon — emissions associated with the manufacturing, installation, and end of life — in the material used.

Insulation is a unique building element specifically used to reduce a building’s operational carbon emissions by lowering the energy required for heating and cooling. However, embodied carbon from fossil-fuel-based insulation can increasingly outweigh these operational savings. In a fully electric building, insulation will still reduce energy demand, but not greenhouse gas emissions associated with heating and cooling buildings.

On the flip-side, bio-based insulation materials have the unique potential to ”draw down” carbon, to reduce both — embodied and operational carbon.

Here is a comparison of insulation materials and the thickness required to achieve R-34, the same R-value our hemplime + wood fiber walls have. The difference between using straw bale insulation and spray foam is 125 kg of CO2e for every square meter of wall.

Scaling Up

According to market research, the global insulation market was USD 61.36 billion in 2022 and is expected to grow annually by 6–7%. EPS currently holds the greatest market share followed by glass wool.

The unique position of insulation in reducing CO2 in the atmosphere is especially potent in the huge market to retrofit or “weatherize” the vast majority of buildings we already built, where in addition to mechanical systems, it is often the only additional material. Insulating already existing buildings IS the low-hanging fruit with an overlooked and outsized potential to store millions of metric tons of carbon in buildings instead of unintentionally increasing the problem. Yet, it is plagued by lack of awareness.

Screenshot of Landing Page of New York State’s Weatherization Assistance Program. Retrieved October 2023

State and local Weatherization Assistance Programs (WAP), which use federal funds to help home-owners reduce their energy needs are thought of as aligning with key climate goals. New York State’s program for instance is seen as playing a critical role in reaching the States 2 Million Climate Friendly Homes goal by 2030. Its landing page image suggests that this will be achieved by spraying foam insulation in attics.

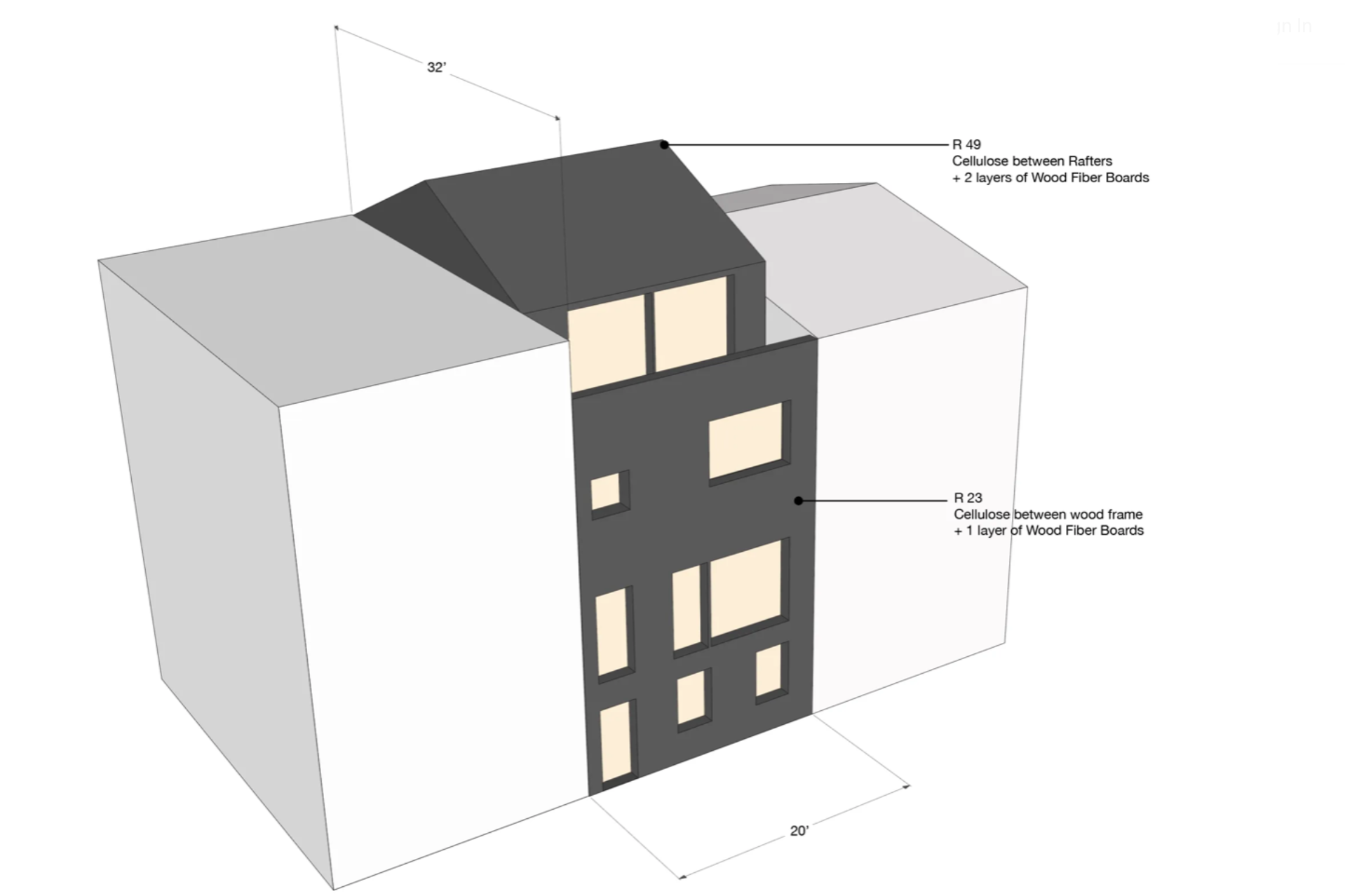

Consider another case study. The renovation of a Brooklyn townhouse, originally built in the 1850s. The envelope-retrofit consists of a mix of cellulose as cavity insulation and wood fiber boards that wrap exterior walls and roof.

This reduced energy demand to approximately 6,000 kWh per year, powered entirely by solar panels on the roof. Here too, the only emissions from this net zero building are embodied emissions from the materials used in the renovation. As a townhouse, with relatively little exterior surface, 1540 sq ft of insulation in walls and roof store approximately 2.4 metric tons of CO2e, the equivalent of what 3 acres of forest store in a year.

Had we instead used a combination of closed cell spray foam and Owings Corning Foamular XPS boards, just the insulation alone would have been responsible for adding 21 metric tons of embodied carbon to the atmosphere, almost twice the annual carbon budget of an average New Yorker.

Scaling up bio-based insulation in the anticipated 2 million weatherization projects in New York alone can either store up to 5 million metric tons of CO2e in buildings or contribute another 42 million metric tons of CO2e to the atmosphere with a business as usual approach.

Bio-based materials become even more convincing when taking a more holistic view of costs and opportunities.

READ MORE

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Help Wanted:

Publications

Hemp Building Directory 2023 - Guide to the International Hemp Building Industry

“Hemp Buildings - 50 International Case Studies” by Steve Allin

Green Builders

Hemp Building Research and Training

Enrolling now Hemp Build School Masterminds online and IRL for Homeowners and Professionals

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Hemp Building Company: Hempcrete Supplies, Training Programs. Longmont, CO

PROducing Sustainable Fibers for Environmentally Conscious Consumers - Prairie PROducers

Grown in USA: Hemp and Fiber specialists at Complete Hemp Processing

Hempcrete installers/Insulation subcontractors

Lime Binder

Hemp Batt Insulation/Supplies

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Blocks

Professional Associations