Trades Workers Learn Hemp Building at Chicago Certification Workshop

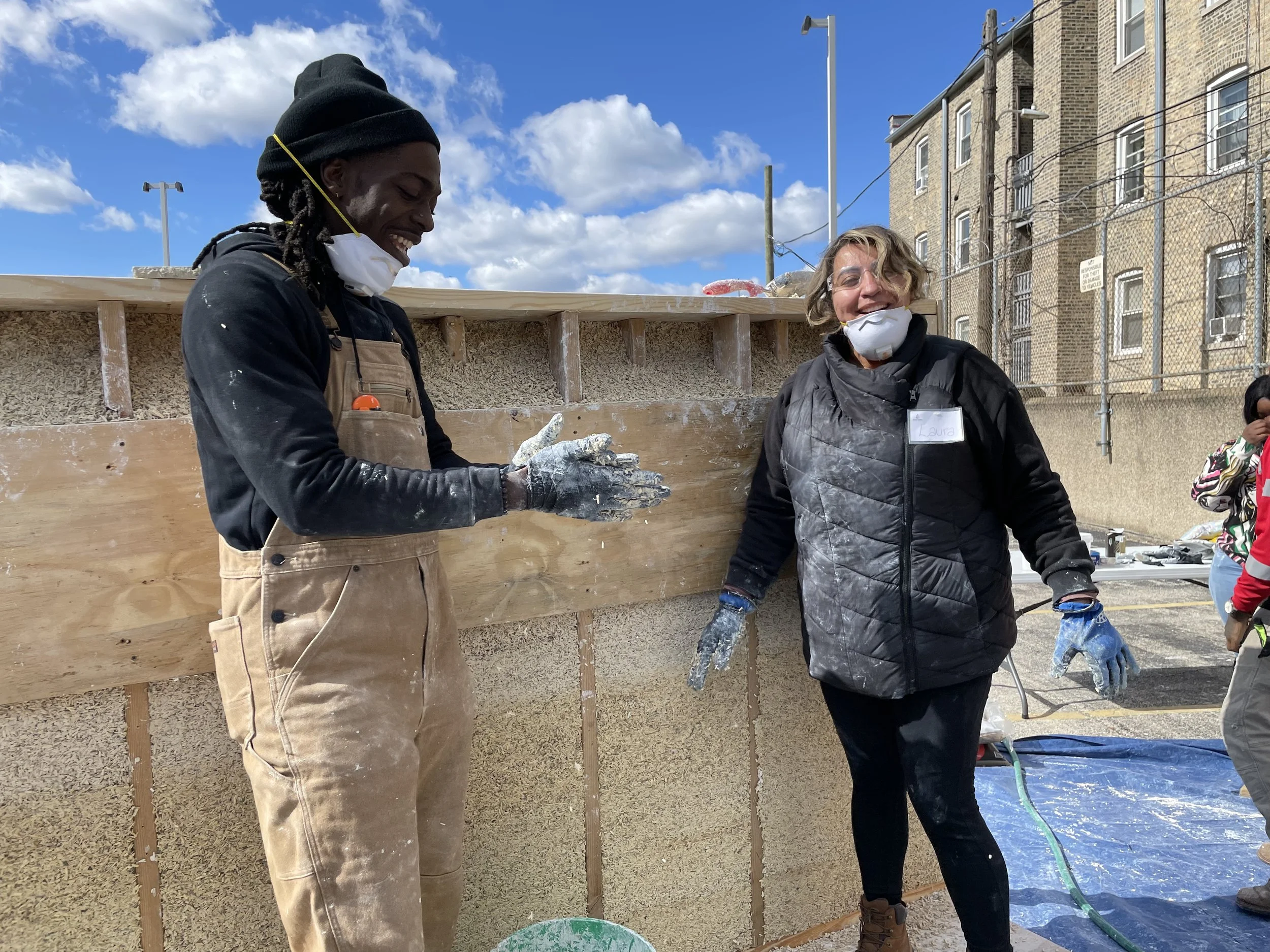

Hemp veteran builder Dion Lefebvre poses in front of a finished hempcrete wall with Chicago carpenter Lamarr Coats, member of Local 174 at the Build Green Hempcrete Workshop in Chicago Oct. 10. Photo by Jean Lotus

By Jean Lotus

Chicago union carpenters and bricklayers got an exposure to hemp-lime materials in a four-day certification workshop led by a Canadian hemp block maker this week. Pink Hats Construction and Development hosted the Build Green Hempcrete Workshop in Chicago’s Uptown neighborhood at St. Augustine’s College.

Fifteen-year hemp building pioneer, Alberta-based Dion Lefebvre, developer of the DiVita Block system and 8th Fire Innovations, led the workshop, attended by about 40 participants. Attendees built two walls, one with hand-cast hemp and one with the blocks.

Brick mason Larry King, a member of Local 21, praised the hemp bricks for their lighter weight after fitting several layers of the modeled bricks between studs in a sample wall frame in 15 minutes. He also praised the ease of cutting the hemp-lime materials.

“Even with the details and pipes and things like that, you can cut this real easy and run everything around it,” Hill said. Hill also said he appreciated the acoustic properties of the walls, which he could tell would muffle sound. He also noted the absence of waste common in the brick industry.

“You reuse everything, and redo it again and keep using it. I like it,” Hill added.

Brick mason Larry Hill of Bricklayers Local 21 talks about working with hemp blocks at the Build Green Hempcrete Workshop at St. Augustine College in Chicago Oct. 9. Photo by Jean Lotus

Lefebrvre’s goal with the bricks is streamlining production, he said.

“We've got to bring this into the mainstream to have mass adoption,” Lefebvre told HempBuildMag. “You see the excitement from these ‘brickies’ here in Chicago,” he said, using an Anglosphere slang term for bricklayers. “It's super inspiring, you know. They're smiling while they're working.”

Tim White, longtime natural builder and founder of Texas Healthy Homes, shared experience with lime and clay plasters used in projects such as the Hondo Hemp House, which won the US Hemp Building Association’s 2023 hemp structure of the year.

Pink Hats Construction co-founders Traci Quinn and Kate Thomas encountered hemp building through Chaze Williams, executive director of the South Carolina Hemp Association, who hosted a building workshop in Charlestown, NC with Root Down Designs and took training with Lefebvre last year.

Quinn’s vision is to bring natural materials and hemp-lime’s pest proof, non-toxic qualities to retrofit Chicago’s built environment where her grandparents and parents grew up.

“If we were to utilize hempcrete in the urban areas and underserved communities, it would be better to help people living with mold and pests,” she told HempBuildMag.

Quinn hopes to license the DiVita Block system and create a midwestern block manufacturing facility, which will produce materials that can be used for retrofitting projects in Chicago and south suburbs such as Harvey, IL.

Pink Hat Construction and Development co-founder Traci Quinn trowels some hempcrete at the workshop. Photo by Jean Lotus

General contractor Melvin Henley, who also runs a West Loop-based workforce development organization PAC Leaders, LLC sees interest in sustainable hemp building materials in Chicago. Henley, whose company has helped with both the Venice and Chicago Architectural biennials.

“I've been wanting to build with these materials for a while,” Henley said. Projects such as the renovation of a decommissioned elementary school in Englewood to become a community center, can provide examples for a prototype structure, Henley believes.

“We really want to show Chicago and the Midwest how to use the product,” he said.

Winnsboro, SC-based hemp farmer Duane Dowton and partners Jimmy and Gude Bernandez came to the workshop because they seek to open a processing facility and sought to learn about the customers who would be buying hemp hurd and other offtake materials. The two had a long history rehabbing and renovating buildings in Baltimore.

“Green is sexy,” Jimmy noted.

Hemp builder Lefebvre said his goal to build relationships is part of his “spirit led” approach to building his business and spreading the hemp-building gospel. This summer, Lefebvre installed his blocks in a retrofit of a 1911 historic General Store in Denton, NE.

Over his decade plus in the business, he has noticed increasing interest from home owners.

“We’re at a tipping point in our consciousness where the consumer is going to be demanding this,” Lefebvre said. “The cottage industry cast-in-place method is great for the DIY-er,” he noted. “But we need hemp building to be adopted by the conventional trades and conventional industry.”

Chaze Williams (L), executive director of the South Carolina Hemp Association, works on a hempcrete wall with St. Augustine College reconstruction apprenticeship student Laura Felix (R) at the Build Green Hempcrete Workshop Oct. 9. Photo by Jean Lotus

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Help Wanted:

Publications

Hemp Building Directory 2023 - Guide to the International Hemp Building Industry

“Hemp Buildings - 50 International Case Studies” by Steve Allin

Hemp Building Research and Training

Enrolling now Hemp Build School Masterminds online and IRL for Homeowners and Professionals

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Hemp Building Company: Hempcrete Supplies, Training Programs. Longmont, CO

PROducing Sustainable Fibers for Environmentally Conscious Consumers - Prairie PROducers

Grown in USA: Hemp and Fiber specialists at Complete Hemp Processing

Hempcrete installers/Insulation subcontractors

Hempknowlogy: Home of the Hempjet: America’s first hempcrete spraying system. Manchaca, TX

Design and build your Hempcrete home with HempStone LLC complete consultants

Lime Binder

Hemp Batt Insulation/Supplies

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Blocks

Professional Associations