Hempcrete: A Master of Moisture Control

By Basit Awan

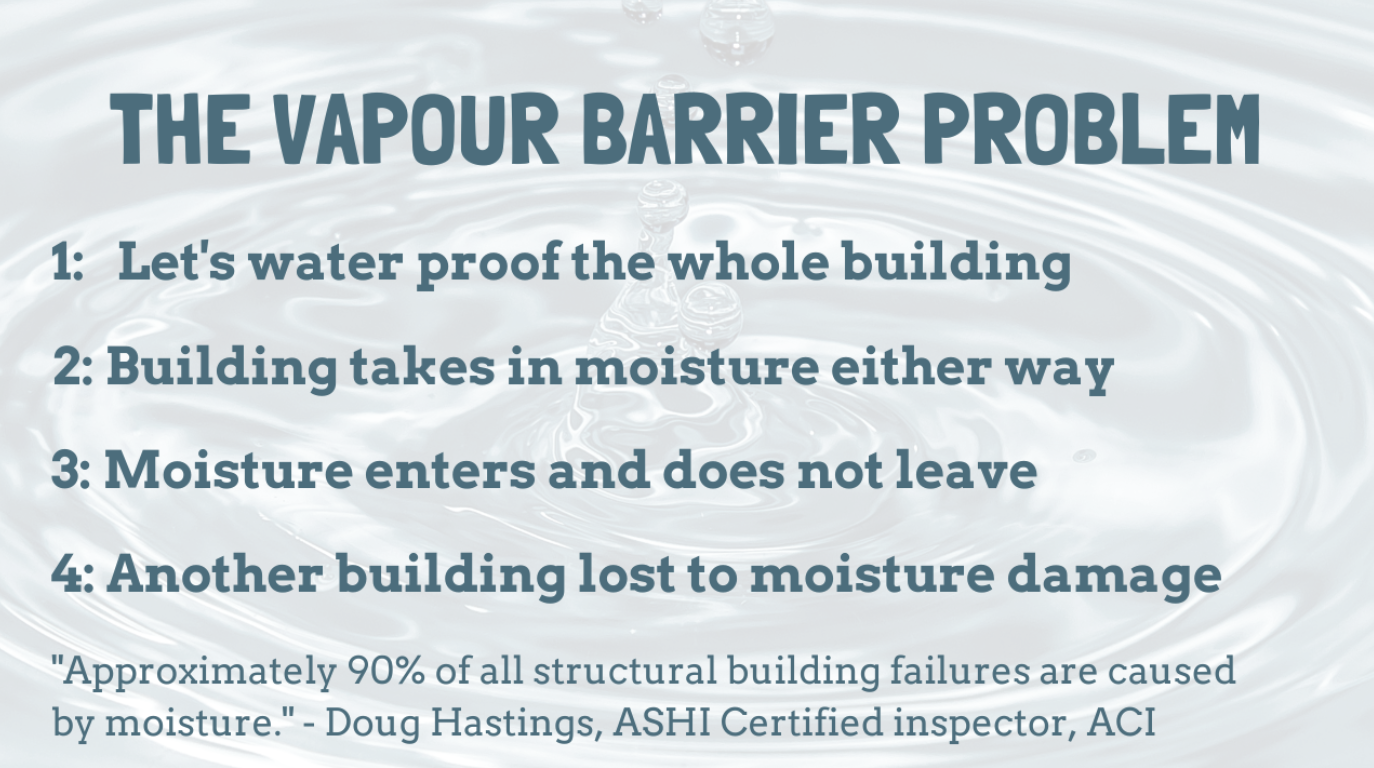

Moisture is one of the biggest problems for buildings as it can rot the structure and bring about mold/other such issues. Most structures fail before their time because of moisture.

Subscribe for HempBuild Magazine’s free newsletter

Why do we need better construction practices that help to manage moisture in our buildings?

Most structures in North America are built as if they are separate from the environment. Under the misconception that if they wrap the building with plastic, it will completely block out the building from all the moisture of the outside world.

Click here to go to our FREE online community.

Unfortunately this misconception has led to the failure of many structures before their time because if a structure is tightly wrapped with plastic, it still takes in moisture but doesn’t let it out that easy. When this happens, the moisture causes rot and damage.

In order for a structure to survive in the environment where moisture is the building block of life, the structure must be able to breathe moisture.

When a structure breathes moisture, it is able to take the moisture in and let it out. This is not only healthy for the building but it is also very healthy for the tenants residing in the building.

How does hempcrete regulate moisture?

“Hemp shiv is a naturally vapour-permeable material, meaning that it allows water vapour to travel through it, thanks to its porous nature: it has a microscopic structure of tiny capillaries created by the cell walls, orientated in the direction of the plant’s stem. This capillary structure accounts for the hemp shiv’s hygroscopic behaviour — its ability to attract and hold moisture from the surrounding atmosphere, releasing it again in response to changes in the humidity of the environment.”

“This vapour permeability may seem an alien concept to anyone who has worked with conventional synthetic building materials over the last 50 years or so, since ‘advances’ in material technologies have often centred on the production of building materials that were intended to form a vapour barrier, keeping moisture out of the building.”

“Bevan and Woolley report that there are several anecdotal examples of test panels of hempcrete being cast and left out in the rain, without rendering, for periods of up to several years without any deterioration of the material, and in spray-testing by the BRE Group, hempcrete performed extremely well in resistance to water ingress”

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Help Wanted:

Training and Education

Publications

Hemp Building Directory 2022 - Guide to the International Hemp Building Industry

Available Now! “Hemp Buildings - 50 International Case Studies” by Steve Allin

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Hempcrete installers/Insulation subcontractors

Lime Binder

Hemp Batt Insulation/Supplies

Green Builders

Hemp Building Engineers

Hemp Genetics

Professional Associations

Events