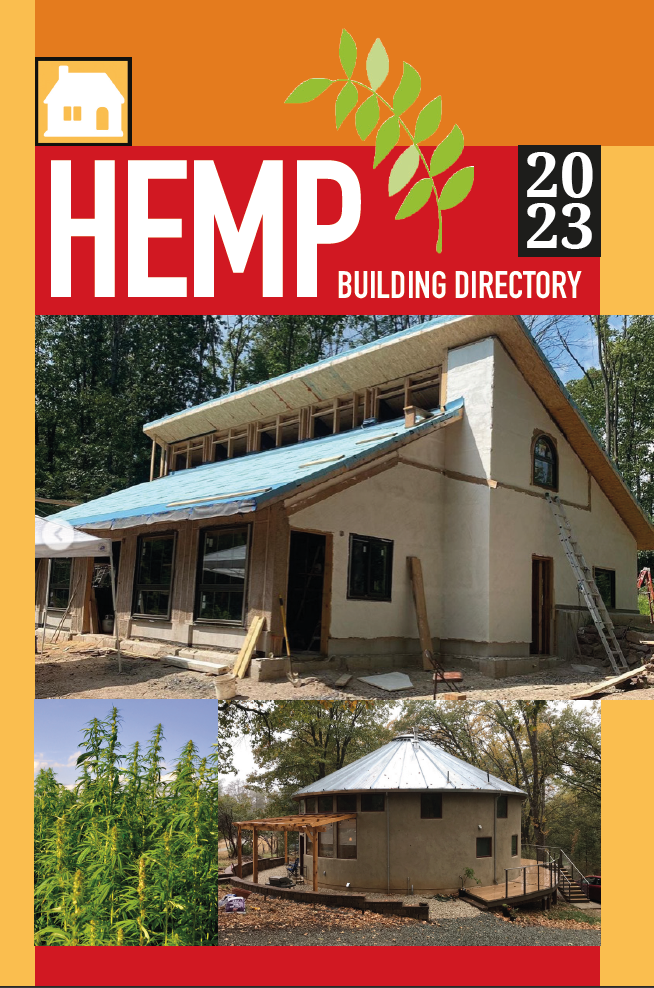

Hemp Building: Looking Ahead for 2023

Hemp building shows signs of moving ahead in 2023 in the $2.7 trillion U.S. building industry . Photo by Harry Sopp.

By Jean Lotus, editor and publisher, HempBuild Magazine

It’s hard to find a more sustainable and regenerative building material than tree-saving hemp. The quick-growing crop’s carbon-capturing superpowers fit naturally into world climate goals from the Paris Accord to COP 27. All have focused on the massive carbon footprint of the construction industry: About 38% of greenhouse gasses are generated by construction, while 25% of the world’s landfills will soon be filled with construction waste, Architecture 2030 reports.

If hemp building products can shave off just a sliver of the annual $2.7 trillion U.S. building industry revenue, the industry can be brought to profitability and prices can lower to match those of conventional construction materials, advocates believe.

Hemp is a cleaner, healthier, recyclable building material that sequesters carbon via photosynthesis while growing, then locks it up for years inside a building’s walls, floors and ceilings. As such, hemp building materials – if adopted on a large scale – could help transform the built environment from a major contributor to greenhouse emissions to a central solution for carbon drawdown.

The year 2023 looks good for hemp building. Let’s look at some of the favorable conditions for the coming year.

Federal Support for Hemp Building Materials

The U.S. political environment is favorable to push hemp building materials into wider circulation, helping to shore up the growing supply chain.

The Biden-Harris Inflation Reduction Act has opened the door to funding sustainable building solutions, including the federal Buy Clean and Green and Resilient Retrofit programs. The General Services Administration (the federal government’s landlord) and other federal infrastructure purchasers are encouraged to use sustainable, low carbon materials. In 2022, Murray, Kentucky-based HempWood was awarded “Biopreferred” status through a USDA program that gives preference in federal procurement to vendors of bio-based products.

The Department of Energy is specifically encouraging hemp building materials in several programs.

The U.S. Department of Energy has focused on hemp building materials.

“Decarbonization is the one word that really gets the Department of Energy excited,” Idaho-based Hempitecture, Inc.’s Tommy Gibbons told a crowd at the US Hemp Building Summit in Austin, Texas, in October 2021.

“They really see hemp as a tool to take carbon out of the air, turn it into value-added products and do that at scale,” he continued. “Decarbonization has become a huge focus of this administration and this Department of Energy; they are willing to go all-in on that.”

Some developments in 2022:

Researchers at Texas A&M University received $3.7 million in DOE funding to study and develop 3D printed hemp-based building materials.

Earth Merchant hemp block company received DOE funding and $100,000 from the Environmental Protection Agency for the Ology hemp block system.

Berkeley Lab’s IMPEL incubator program has supported hemp building material businesses to develop new building products. Colorado-based HemProtector and Indianapolis-based Gaia Blocks are companies in the current cohort. In previous cohorts, California-based okom wrks labs, developing a mycelium hemp load-bearing material, received Series A funding. Idaho-based Hempitecture Inc. was awarded a two-year fellowship at the DOE’s Oak Ridge laboratory to perfect its U.S.-grown hemp batt insulation for manufacture in a newly built Idaho facility.

In 2023, expect to see more support for hemp building products from government initiatives, especially under the new federal focus on Nature-Based Solutions.

States Crack Down on Embodied Carbon in New Construction

Additionally, states and municipalities are cracking down on high-emission building practices and materials that drive up “embodied carbon” in a structure.

California passed Assembly Bill 2446, which mandates that the carbon footprint of newly constructed buildings be reduced by as much as 40% by 2050. New York and New Jersey also have passed greenhouse gas-reducing rules for new construction, as have the cities of New York and Vancouver, BC.

Hemp can sequester tons of carbon within a single building, slashing the total greenhouse gas ledger to low or even zero-carbon. Voluntary carbon credits and rebates may also play a role in making hemp buildings more attractive and financially attainable to both consumers and construction companies.

Accepted Into U.S. Building Codes

Another star shining for hemp building materials going forward is its certification in 2022 in U.S. residential building codes. Hemp-lime wall infill, nicknamed “hempcrete,” was approved by the International Code Council as an acceptable insulation in an appendix of the International Residential Code. The new approval “will make it easier for building departments to review plans for permitting [hempcrete]. This provides prescriptive guidance for a sustainable option for wall infill,” the ICC said.

Appendix BA will allow the use of hemp-lime in one- and two-story buildings in regions of low seismic risk prescriptively without engineering. Regions of high risk will require an engineered design.

“Code induction of a natural building material of any type is really big news,” Anthony Dente of California-based Verdant Structural Engineers, who submitted structural engineering data for the proposal, told HempBuild Magazine. “The IRC Hemp-Lime Appendix is an excellent foundational document with a lot of really exciting areas of potential growth in the future.”

Roadmap for Quick Adoption

Hempcrete is made from lime powder mixed with the chopped up inner bark of the plant, called the hurd or shivs. In a fiber hemp variety, hurd is about 50% of the output of a bale of processed hemp. The outer bark, or bast, generates about 20% each of long fiber (used in textiles and rope) and short technical fibers, which are often used for fiber-based nonwoven building materials. About 8% of the processing output is dust or microfibers, which can be used in plasters and even plastics.

Hemp-lime has been used for insulation for 30 years in Europe. For that reason, insulation values, thermal mass, and fire and mold resistance have already been tested and tweaked. This gives the U.S. hemp builders a path to quickly ramp up uses of the material.

Additionally, Europeans have already developed and are waiting to license other products, such as hemp acoustic panels, batt and blow-in insulation, drywall, fiber board, structural insulated panels (SIPs) and hemp blocks.

US Trade Organization Building Momentum

The US Hemp Building Association will continue to grow in 2023 with a new board of directors and more visibility in the building world. The association and its sister non-profit foundation were victorious in acquiring adoption in the US residential building codes. Look for more news from USHBA, including special hemp-building events around SXSW in Austin, TX this March.

Hemp Blocks Will Emerge

New US-based hemp block companies are starting up in 2023, including Colorado-based Hemp and Block and Hemp Building Company. Other US-based block companies such as Washington-based Earth Merchant, GaiaBloc from Indiana and California-based DTE Materials will likely be rolling out new products this year. Several international hemp block companies are likely to make inroads in the United States this year. Alberta, Canada-based DiVita Blocks is already partnering in California, South Carolina and elsewhere to franchise the block system, which fits between house framing studs. European companies with their eyes on the U.S. hemp block market include HempBLOCK International, which licenses the interlocking BioSys block from Groupe Vicat in France, and Belgium-based blockmaker IsoHemp.

Innovation in the USA

Additionally, innovators and tinkerers have been excited by the introduction of a brand-new building material, formerly prohibited under federal law, spurring them to create new products.

Some ideas now in R&D that may break the surface in 2023:

Load-bearing bricks made with biocomposite using hemp as an aggregate

Hempcrete and hemp materials made with quick-setting magnesium oxide instead of lime

Panel-based hemp modular tiny homes for ecotourism

Hemp fiber continuous insulation sheathing product to replace foam sheets

Hemp-based OSB or fiber board

Hemp + plastic waste fence, cladding or decking material similar to Trex

Hemp-mycelium building products that can be grown in molds.

Hemp building materials certainly advanced quickly in the United States in 2022 and will continue to speed forward in 2023. A market in the building sector from fiber hemp processing can’t help but generate more raw materials at scale for other parts of the supply chain, such as biofuels, plastics and textiles.

Overall, the stars are aligning for hemp building materials and fiber hemp in 2023.

The combination of regulatory friendliness plus a proven international technology and a government and social focus on sustainability will be a stable platform to support fiber hemp and the sustainable building materials it generates.

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Help Wanted:

Publications

Hemp Building Directory 2023 - Guide to the International Hemp Building Industry

Available Now! “Hemp Buildings - 50 International Case Studies” by Steve Allin

Hemp Building Research and Training

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Hemp Building Company: Hempcrete Supplies, Training Programs. Longmont, CO

PROducing Sustainable Fibers for Environmentally Conscious Consumers - Prairie PROducers

Hempcrete installers/Insulation subcontractors

Hempknowlogy: Home of the Hempjet: America’s first hempcrete spraying system. Manchaca, TX

Design and build your Hempcrete home with HempStone LLC complete consultants

Lime Binder

Hemp Batt Insulation/Supplies

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Blocks

Professional Associations

Events

Carbon Zero Building with Hemp Materials SXSW, Austin TX March 11, 2022