Supply Chain: Hempitecture Partners with Montana’s IND Hemp

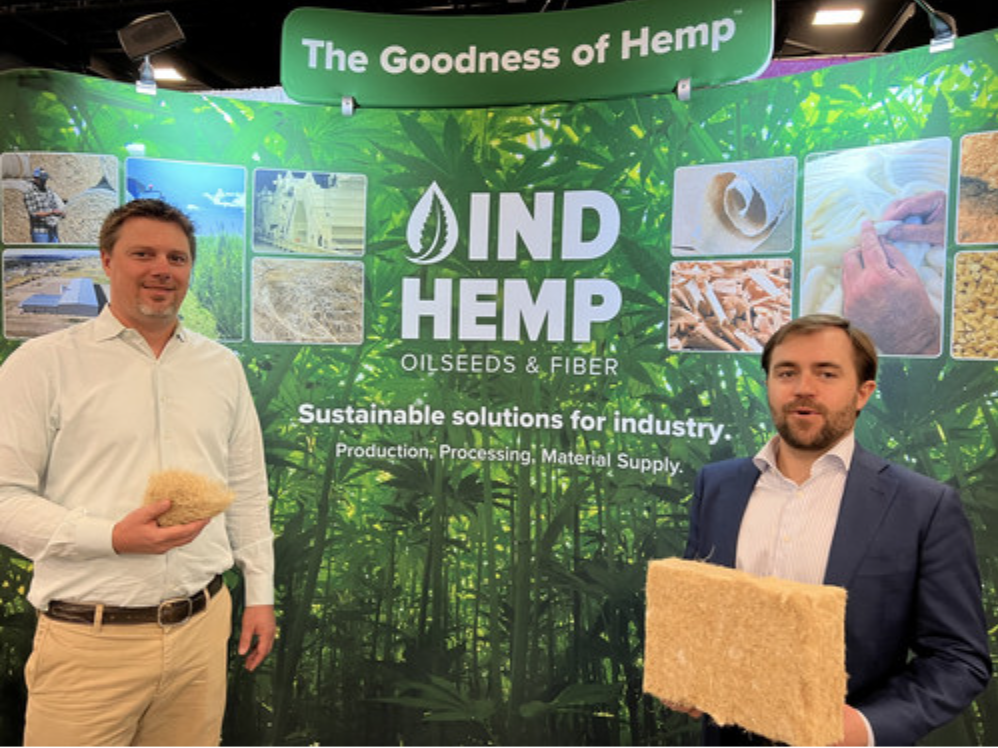

IND HEMP Chief Strategy Officer Trey Riddle, PhD (L) and Hempitecture CEO Mattie Mead (R) show off the raw hemp bast fiber and finished Hempwool® insulation product. Photo courtesy of Hempitecture, Inc.

By Jean Lotus

Hemp fiber batt insulation will be made in Idaho with US-grown hemp thanks to a partnership inked in March between Hempitecture, Inc. and Benton, Montana-based IND Hemp, a decortication and processing company.

Hempitecture raised $4.6 million in Wefunder crowdfunding seed-round investment from 1,827 investors for the company’s new Jerome, ID facility that will make batt fiber insulation from hemp. Hempitecture has previously imported its HempWool batt insulation from Quebec-based Nature Fibres.

The two firms agreed to a supply-chain partnership that will process industrial hemp from crops grown in Montana, Oregon, Washington and Idaho through IND Hemp. IND Hemp’s 52,000 sq. foot production facility decorticates about 5 tons of hemp per hour with a LAROCHE bast fiber decortication processing line that has just come online, the company said.

"IND HEMP is dedicated to supporting rural economies and providing sustainable solutions to industry. We are excited about Hempitecture's products and use of natural fiber in construction materials. This continues to showcase how IND HEMP's products and sustainability benefits can be adopted successfully across a wide range of applications," said Trey Riddle, Chief Strategy Officer for IND HEMP in a statement.

Subscribe for HempBuild Magazine’s free newsletter

Hemp can capture and remove more CO² from the atmosphere per acre annually than a forest or most other agricultural crops.Hemp sequesters carbon in the soil while growing but the quick-growing plants also sequester carbon while growing above ground during photosynthesis. Plant biomass contains an average of 45% carbon, the companies said.

That Co2 is then locked in the walls of a home when the fibers are processed into insulation and built into walls. Hemp fiber insulation also counteracts the carbon footprint of greenhouse- gas emitting glass fiber and mineral wool insulation, which contribute more than 30 percent of the stratospheric ozone depletion, the worst environmental culprit, in the “pre-construction phase” of single-family homes, according to the Environmental Protection Agency.

Hempitecture co-founder Mattie Mead, in a statement, called the partnership ”the restoration of American manufacturing, the empowerment of rural economies and forward thinking innovation in sustainable materials.”

Click here to go to our FREE online community.

Last year, Hempitecture partnered with the U.S. Department of Energy’s Building Technologies Research Integration Center at Oak Ridge National Laboratory in Tennessee to develop and commercialize new hemp-based building products.

Please Support Our Classified Advertisers

〰️

Please Support Our Classified Advertisers 〰️

(To find out more about advertising CLICK HERE).

Help Wanted:

Training and Education

Publications

Hemp Building Directory 2022 - Guide to the International Hemp Building Industry

Available Now! “Hemp Buildings - 50 International Case Studies” by Steve Allin

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Hempcrete installers/Insulation subcontractors

Lime Binder

Hemp Batt Insulation/Supplies

Green Builders

Hemp Building Engineers

Hemp Genetics

Professional Associations

Events