The Carbon Impact of Our Buildings

Embodied carbon reductions in the built environment can be achieved using hemp materials on the market today. Image courtesy of Hempitecture

By Jonnie Pederson

Operational Carbon X Embodied Carbon

When the world came together and signed the Paris Climate Agreement in 2015, we witnessed almost 200 countries set their vision towards the goal of limiting global temperature, keeping it below the catastrophic 2°C tipping point. Generating nearly 40% of Greenhouse Gas emissions (GHG), the built environment creates more emissions than any other sector of the economy — more than transportation, agriculture, and industry. This situation needn’t be so, as we have the means to greatly reduce or eliminate operational carbon from the building sector. If we can eliminate carbon emissions from the built environment, we can significantly reduce overall emissions and potentially solve the climate change crisis.

Operational Carbon

Operational carbon refers to the total from all energy sources used to keep our buildings warm, cool, ventilated, lighted, and powered. Typical energy sources for this purpose are electricity and natural gas, with occasional contributions from fuel oil, propane, and wood. The “carbon” part of operational carbon is a stand-in for all the GHGs released from these many energy sources and is the total of all GHGs released by them. You will occasionally see the abbreviation “CO2e” which signifies carbon dioxide equivalent.

Since the beginning of the green building movement in the 1970s, the design community has focused on mainly increasing the efficiency of operating a building - reducing the energy consumed and carbon emitted. Zero Net Carbon (ZNC) is the gold standard for sustainable construction, but shifting the operation standard of a building isn't enough for the climate task at hand.

Embodied Carbon

In the building industry, embodied carbon refers to the sum of all the greenhouse gas emissions (mostly carbon dioxide) resulting from the mining, harvesting, processing, manufacturing, transportation, and installation of building materials. The embodied carbon footprint is therefore the amount of carbon (CO2 or CO2e emission) to produce a material.

Embodied carbon is often 20-50% or so of the whole life energy and carbon of a building. In contrast, operational carbon refers to the greenhouse gas emissions due to building energy consumption.

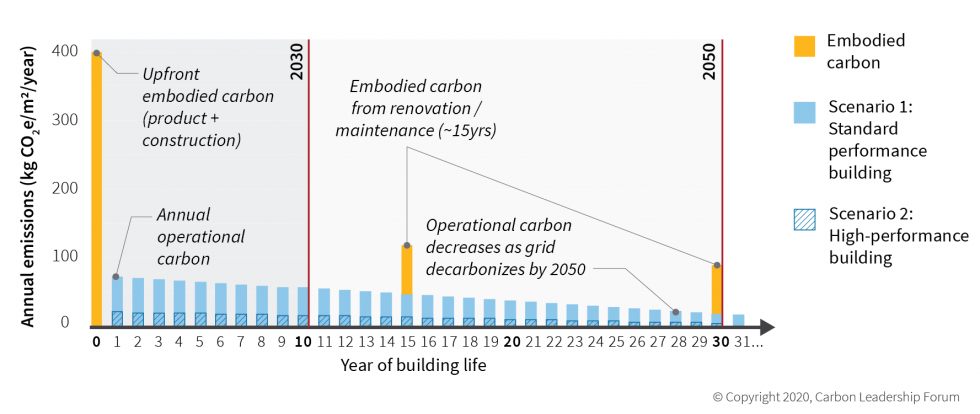

Image coutresy of Carbon Leadership Forum

Scientists use a method called Life Cycle Assessment (LCA) to track the emissions produced over the full life cycle of a product or process, in order to measure their potential effects on climate change. These greenhouse gas emissions are converted into metrics that reflect their potential effects on the environment. One of these metrics is global warming potential (GWP), which is quantified in kilograms of CO2 equivalent (kg CO2 e). This quantity is also commonly referred to as a carbon footprint.

The majority of a building’s total embodied carbon is released upfront in the product stage at the beginning of a building’s life (see Figure 2). Unlike operational carbon, there is no chance to decrease embodied carbon with updates in efficiency after the building is constructed. There is an urgent need to address embodied carbon now to meet short-term and long-term climate targets.

Image coutresy of Carbon Leadership Forum

As building operations become more efficient, managing the embodied impacts related to producing and installing building materials becomes increasingly significant. Relevant embodied carbon reductions can be achieved using materials on the market today. Carbon-storing materials, both bio-based (such as HempWool®) and mineral-based (e.g., concrete utilizing carbon capture and storage (CCS) technology), demonstrate the viability of using building materials to store carbon.

When looking at total greenhouse gas emissions for new buildings built over the next ten years — the critical period for action to address the global climate emergency — Architecture 2030 estimates that 80% will come from embodied emissions, so lowering embodied carbon emissions is now even more urgent than lowering operating emissions.

While major renovations where we apply Zero Net Carbon standards are an important part of decarbonizing the built environment, it is crucial to consider immediate embodied carbon impacts when constructing. To have any hope of meeting our climate change goals, we must rethink our traditional mechanisms and design processes in renovations and architecture.

Where to start?

Get educated about embodied carbon

Learn more about new tools, products, and alternative materials available

Set goals for reducing embodied carbon on each project

Focus on high volume materials: Between 50% and 75% of embodied emissions typically come from the concrete and steel in the foundation and structure.

Focus on high emission materials: For example, small amounts of aluminum and certain kinds of foam insulation can have very large emission footprints.

Resources

Carbon Leadership Forum

"The New Carbon Architecture" - Bruce King

Tally – embodied carbon calculator utilizing Revit.

Athena – Life Cycle Analysis (LCA) and carbon calculator

ICE – British database of embodied energy and carbon of materials

EPDs – Environmental Product Declarations

Jonnie Pederson is Growth Operations Manager at Hempitecture, Inc. This post originally appeared here.

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Training and Education

Publications

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Hempcrete installers/Insulation subcontractors

Haven Earth PMA: Bio-Design and Conscious Project Management Consultancy

Hempknowlogy: Home of the Hempjet: America’s first hempcrete spraying system. Manchaca, TX

Lime Binder

Hemp Batt Insulation/Supplies

Green Builders

Hemp Building Engineers

Hemp Genetics

Professional Associations

Evants