Hemp Building Regains Momentum in Carolinas

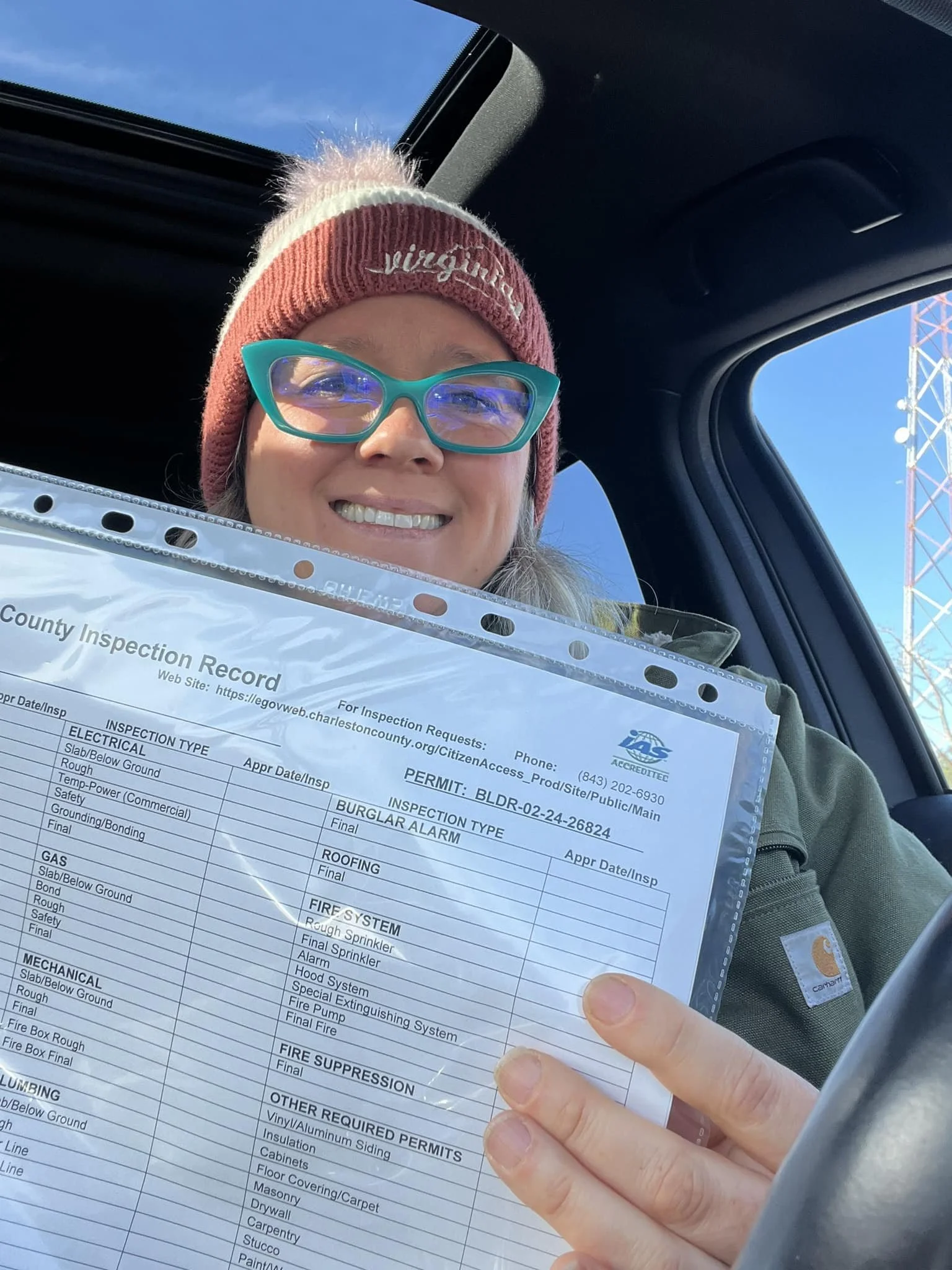

April Magill, Charleston, SC-based architect from Root Down Designs shows off her building permit for a prototype hempcrete structure planned for next year. Courtesy of Root Down Designs

By Jean Lotus

Two long-experienced natural building experts are bringing the Carolinas—North and South—together to revive the region’s hempcrete building scene. April Magill, of Root Down Designs, an architect from Charleston, SC has partnered with North Carolina’s Tim Callahan, a legendary hemp-building pioneer who designed and constructed 10 hemp structures around Asheville, NC between 2009-2016.

The two are working together to bring more attention to hemp-lime as a “climate-smart” construction material that mitigates mold in the humid, semi-tropical climate of the Carolinas.

Both designers have a long history of working with natural materials and hempcrete, stretching back even before the 2018 Farm Bill re-legalized industrial hemp to be grown in the United States.

A private home near Charleston, SC was built with hempcrete blocks last year to mitigate risk for mold. Photo courtesy of Caroline Smythe.

“The truth is for most people in our region, especially because of our climate, I just don't know anything that will perform the way that hempcrete does,” Callahan told HempBuild Mag.

“If you use hempcrete on exterior walls, the odds of you having any mold issues, unless you just do something really egregious, are approaching zero. That’s a big deal for people’s health,” he added.

A private hempcrete home was built last year near Charleston inspired by the owners’ desire to avoid mold.

Magill’s non-profit Root Down Building Collective is raising money for a prototype permitted hempcrete structure of 350 sq. feet to measure indoor air quality and moisture control.

The Charleston Healthy Housing Project is a way to develop a panelized, natural building system “that could work for affordable housing projects, emergency housing and senior housing,” Magill told HempBuild Mag.

Sketch of proposed hempcrete prototype house. Courtesy of Root Down Building Collective.

Magill and Callahan will host hempcrete workshops this summer. The two natural building experts, Magill and Callahan, are also teaming up to release hempcrete house plans in the near future.

After almost 10 years with “minimal web presence” and staying out of hemp building, Callahan has jumped back into the hemp-lime design business after he helped to co-author the hemp-lime appendix in US residential building codes to be adopted by the International Code Council later this spring.

In a feverish spate over about eight years starting in 2008, Callahan designed and worked on multiple hempcrete homes, including the now-famous NauHaus in Asheville. Some of them were very large and luxury buildings.

A luxury hempcrete home designed and built by Tim Callahan near Asheville, NC in 2016-17. Photo courtesy of Tim Callahan

Inspired by the Architecture 2030 movement in the late 2000s, Callahan and a business partner and later co-author of Building Green determined that they were “ridiculously idealistic” and small enough that “we’re gonna do this right now. We don’t have to wait [for 2030], let’s just give this a shot.”

But his focus has always been to try to “mainstream” the use of hempcrete in building.

“I remember, around 2010 standing in the middle of our first boutique project, which was quite large and over-the-top, and saying, we’ve learned a lot, but if we just do this one time, all this effort is wasted.”

With the new building codes, Callahan believes, working with hempcrete is “opened up to a lot of people.”

Tim Callahan

Leaving commercial architecture

Magill’s interest in natural building methods happened when she “left commercial architecture” about 2011 and started to look at historic natural building methods and materials in the Southeast United States, some imported from Africa by enslaved people.

The 150-year-old Church of the Holy Cross near Sumter, SC and some of the enslaved-built buildings on the Borough House Plantation were made of rammed earth.

“That was a big moment for me and it led me to more research through Clemson and other universities, that tracked this history of earthen building construction coming here through the slave trade,” she said.

Eventually, she said, she realized the climate in South Carolina is not well suited to adobe or earthen building. Magill learned about hempcrete from natural builder and Canadian climate-smart building expert Chris Magwood and then met Callahan at a natural building conference in 2011.

Click here to go to our FREE online community.

“[Magill] is one of the few architects that is actually interested in natural building,” Callahan said, “She likes to experiment with things and has a ‘quest for truth.’ – Maybe I’m getting a little dramatic here,” he added. “But people’s health and safety depend on our environments.”

After years of teaching natural building at the local American College of Building Arts, in Charleston, Magill said, she’s now being asked to speak to the local chapter of the Natural Association of Home Builders.

“I've been doing alternative construction work for over a decade,” Magill said “And nobody's ever really taken it seriously. But recently they’re asking me to come talk about this stuff. There's a shift that is most certainly happening,” she said.

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Help Wanted:

Publications

Hemp Building Directory 2024 - Guide to the International Hemp Building Industry

“Hemp Buildings - 50 International Case Studies” by Steve Allin

Green Builders

Build your hempcrete dream house in Austin, TX with Gradek Contracting and Design

8th Fire Innovations: 15 Years of Hemp Building in Alberta, Canada. Home of the Divita Block System

Experienced Natural Building Engineering Services from Verdant Structural Engineers, CA

Natural Materials Design at Plural Office Architects, Austin TX

Hemp Building Research and Training

Enrolling now Hemp Build School Masterminds online and IRL for Homeowners and Professionals

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Your Hemp Agricultural Solutions: Whitefield Global Holdings

Grown in USA: Hemp and Fiber specialists at Complete Hemp Processing

Hemp Building Supplies, No Order Too Small. Hemp Traders, Los Angeles

Hempcrete installers/Insulation subcontractors

Hemp Build Network: We Make Building with Hemp Possible, New Braunfels, TX

Hemp Building Company: Hempcrete installation, supplies Lafayette, CO

Design and build your Hempcrete home with HempStone LLC complete consultants

Lime Binder

Hemp Batt Insulation/Supplies

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Blocks

Financial Services:

Professional Associations