Hempitecture Rolls Out $5M Equity Raise

Students from the University of Idaho visit the Hempitecture plant with co-founder Mattie Mead (2nd from Left). Photo courtesy of Hempitecture.

By Jean Lotus

Idaho-based Hempitecture, Inc., manufacturer of US-grown hemp insulation batting HempWool, plans to open a second manufacturing facility in New York state and roll out several new products in 2024, founders say.

Plans are underway to open a new factory, with funds raised in-part from a new equity raise of $5 million via a crowdfunding campaign to be opened March 5 on the WeFunder platform. The company’s previous WeFunder campaign in 2021-2022 raised more than $4.6M from around 1,800 individual investors.

Hempitecture is a public benefit company founded by Mattie Mead and Tommy Gibbons in 2018 and is the first US company to manufacture US-grown hemp fiber batts in the United States.

Hempitecture won $500,000 at Cornell University's Grow New York competition in 2022, setting the stage for a new east-coast facility in either the Finger Lakes or Western NY regions, Gibbons told HempBuild Mag.

In addition, the company is rolling out new products including a hemp FiberPad carpet underlay and a “Plant Panel” continuous insulation board in sizes ¾ inch and 2” thick.

The company is also working on a fire-rated product for its insulation batts “HempWool+” with fire testing through ICC-ES. Additionally, the company will develop a loose-fill insulation product from waste fiber, according to the WeFunder website.

Hempitecture co-founders Mattie Mead (L) and Tommy Gibbons (R). Photo courtesy of Hempitecture.

Hempitecture’s batt insulation was developed as a carbon-sequestering, non-toxic alternative to the $5 billion fiberglass insulation market.

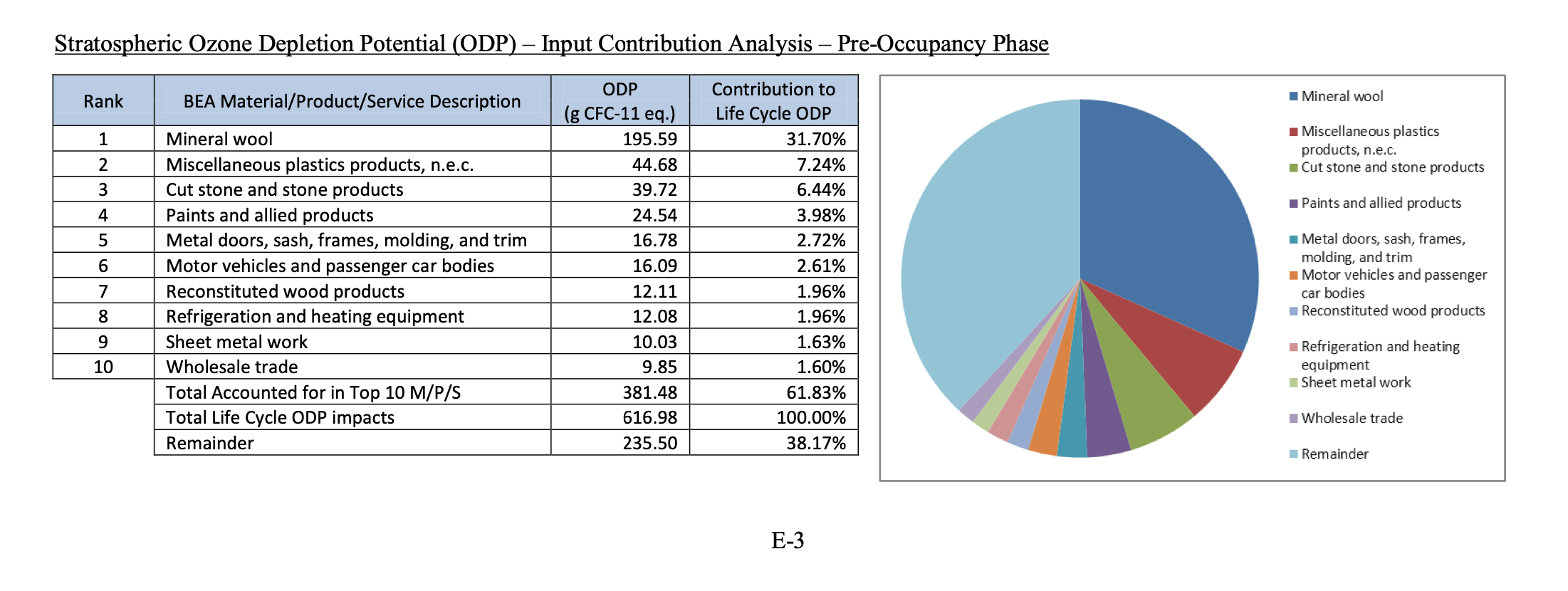

Fiberglass and mineral wool insulation contribute more than 30 percent of the stratospheric ozone depletion, the worst environmental culprit, in the “pre-construction phase” of single-family homes, according to the U.S. Environmental Protection Agency.

Mineral wool is the top product in new homes causing stratospheric ozone depletion, according to the EPA. Source: ANALYSIS OF THE LIFE CYCLE IMPACTS AND POTENTIAL FOR AVOIDED IMPACTS ASSOCIATED WITH SINGLE-FAMILY HOMES, EPA, 2015.

“We are on a mission to turn building materials into carbon storage devices,” co-founder Mead has said.

To help home builders evaluate the costs and benefits of their products, the company publishes prices on its website in full transparency, Gibbons said.

“But if you try and find Rockwool's cost per square foot, you're not going to find it on their website,” he observed.

Hempitecture has opened around eight warehouses in the United States, with the most recent in Minnesota, Gibbons said. Additionally, the company was selected by Boston-based green-tech incubator GreenTown Labs.

The company started building with hemp-lime but then pivoted to hemp-based batt insulation, Gibbons said. Hempitecture still sells hempcrete supplies, including a single hemp-hurd and lime binder product.

“That's really a reflection of the way people build in the United States,” Gibbons said. “It’s the American construction industry – what its priorities are and what it's willing to tolerate when it comes to doing different products.”

“Our focus is on HempWool which has a much faster sales cycle. We obviously produce that product in Idaho and we’re using Idaho grown hemp fiber, which is quite exciting.”

Click here to go to our FREE online community.

But even though sales of HempWool grew 50% in 2023 and are up to 200% so far year-over-year in 2024, the company still faces challenges, Gibbons said. The company’s 2022 SEC filing reported sales of $627,000.

“We are operating a new company in a cut-throat building materials space where there's a lot of established competitors, and there's huge capital expenses and huge labor costs and huge rent,” Gibbons observed. “Making it all and launching stuff is easy. Selling it is hard. And handling it is hard.”

Still, the company persists, with HempWool used on more than 1,500 projects, sequestering 1.2 million pounds of CO2. The company projects sales of $1.5 million for 2024, based on early data, according to WeFunder.

HempWool customers are also able to receive tax write-offs and incentives for weatherproofing their homes from programs such as the Inflation Reduction Act tax rebates, EnergyStar, the Better Building Initiative and others.

“I guess from where I stand is, you know, we're really at an inflection point,” Gibbons said. “The growth is there and the trends are looking good.”

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Help Wanted:

Publications

Hemp Building Directory 2024 - Guide to the International Hemp Building Industry

“Hemp Buildings - 50 International Case Studies” by Steve Allin

Green Builders

Build your hempcrete dream house in Austin, TX with Gradek Contracting and Design

8th Fire Innovations: 15 Years of Hemp Building in Alberta, Canada. Home of the Divita Block System

Experienced Natural Building Engineering Services from Verdant Structural Engineers, CA

Natural Materials Design at Plural Office Architects, Austin TX

Hemp Building Research and Training

Enrolling now Hemp Build School Masterminds online and IRL for Homeowners and Professionals

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Your Hemp Agricultural Solutions: Whitefield Global Holdings

Grown in USA: Hemp and Fiber specialists at Complete Hemp Processing

Hemp Building Supplies, No Order Too Small. Hemp Traders, Los Angeles

Hempcrete installers/Insulation subcontractors

Hemp Build Network: We Make Building with Hemp Possible, New Braunfels, TX

Hemp Building Company: Hempcrete installation, supplies Lafayette, CO

Design and build your Hempcrete home with HempStone LLC complete consultants

Lime Binder

Hemp Batt Insulation/Supplies

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Blocks

Financial Services:

Professional Associations